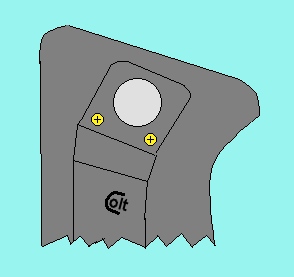

For those of you wanting to do as little modification as possible, you can try the one I did. If you look at the diagram below, you'll see I added two additional screws (shown in yellow) to hold the clip. These are #0-80's:

I had some bad information that my local friendly knife dealer gave me published here for a while. Someone wrote and told me it was wrong, and I finally confirmed that today.

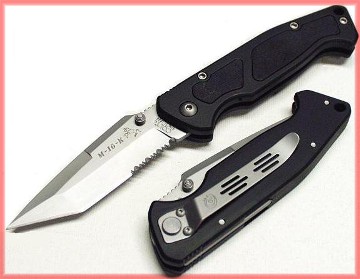

Bottom line -- the "M-14 Sniper" knife

is a different knife than the "Colt M-16", and is made by a different company.

A summary:

|

|

|

|

Double-Action? |

|

|

Blade Markings |

| AR-15 | Colt |

|

|

Thin black painted | Black only | AR-15 |

| M-16 | Colt |

|

|

Thin black painted | Black only | M-16-K (horse)

Colt (r) Since 1836 |

| M-14 Sniper | ???? |

|

|

Thick matte silver | Many | M-14 Sniper

440 Stainless E.D.C. |

All things considered, the Colt knife is the better made of the two -- but they really are made about as close as a rip-off copy knife could be. A quick comparison:

If you have trouble finding these, write Mark Streitenberger at info@mjsknives.com. Tell him Chris sent you!

So, you've bought your Colt M-16 auto, double-action knife. This is an "auto" version of their AR-15-K knife. Quite an amazing deal, isn't it? Colt name brand, and not only an auto knife -- a double-action! I haven't ever seen a truly mass-produced double action knife, have you? And it is one of the most "covert" or hidden double action knife I've seen, with a truly accessible yet hidden release mechanism. And to top all that off -- only about $75-80!

Yes, it's perfect -- almost. Why is it so finicky? Why must it be set so loose that the blade practically rattles when it is open? Not even close to the solidness of a Benchmade 2500. Why, and what can be done? Let's look.

First off, this isn't a coil spring knife -- it uses a flat spring which wacks the blade and it coasts open. It is essential to have no binding in this style of knife so they are typically a tad looser. Not a lot to be done here other than keeping it clean and lightly lubricated. I prefer powdered graphite, you can try some space age stuff -- just don 't make a dust-trap out of it. (BTW, always store flat-spring knives open -- and I'd keep it open at night when not being carried.)

Second -- it may be a Colt, but it ain't a Benchmade. The blade bearing surfaces on the handles are cast, not CNC machined, so the blade must be set looser to compensate. What can be done? Repetitive cycling of the knife will equalize all with use. Don't try any other corrective work unless you are a true pro.

Last, but certainly not least, is a minor design flaw in the knife. Fixing this flaw is what this article is really about.

The

Design Flaw

The spring clip is mounted via the same

fastener that is the blade pivot, the same fastener that is adjusted to

adjust how tight the blade is. When the spring clip is depressed

in the center it pulls upon this fastener with substantial leverage.

This tightens up the blade pivot. So, you get it adjusted "just right",

try it 50 times. Then you really need it, you grab it hard pressing

in on the clip, it tightens up the pivot, and the knife fails to open fully.

What to do? Two options.

Option

One

First option is to remove the clip entirely.

This is a bad idea, at least for me, because I never carry an auto knife

loose in my pocket. It is always clipped on the front edge of my

pocket, inside the pocket where I can instantly find it and it isn't concealed

(as in CDW). You could add a different clip, steal one from a Benchmade

2500 and mount it at the other end.

Option

Two

For those of you wanting to do as little

modification as possible, you can try the one I did.

If you look at the diagram below, you'll see I added two additional screws

(shown in yellow) to hold the clip.

These are #0-80's:

More

Problems

So, all is perfect with your knife

now? Good. Mine still had another serious problem. I

canít blame this one on Colt though. I know for a fact that my knife

did come as a ďkitĒ from Colt as was assembled by the gentleman who sold

it to me. Colt sends these out as quite a kit package, complete with

Allen wrenches. They make most of these as kits so they can move

them across state lines without being arrested.

The kit is not as trivial to put together as some seem to think, there really are part adjustments needed. In the case of my knife, the blade did not close far enough, actually leaving the razor sharp point sticking out in harms way just a bit. This was not at all acceptable, so I made a few adjustments and pulled the tip in by a good ¼Ē.

If your knife shares this problem, here is what to do. If you aren't careful and donít have some experience working with knives, please donít try any of this.

First, remove the auto spring and see if the back-lock would pull the blade in a lot farther if the auto spring wasnít in the way. This was the case with my knife. If it is not the case with yours Ė write me and tell me how you finally fixed it. ?

The first thing you want to do is trim

the end of the auto spring. Under no circumstances should you shorten

the overall length of this spring. You can put a profile on it, but

the full length is essential for operation. Look at the diagram below:

See how metal has been removed from the

area of contact between the spring and blade when the knife is closed.

Go slowly Ė itís harder to put material back than to remove it. And,

again, donít shorten the overall length Ė leave at least ½ the spring

thickness at full length.

If trimming the spring does not pull the

blade in enough, you can carefully remove material from the blade where

it is touched by the spring when closed. Be gentle, go slowly, and

donít make a mess Ė that part of the blade is visible when open.

You should polish it up when you are done.

Update Mar-2004

Colt has fixed these problems in their new version, and exactly as I suggested -- think they read any of this? :)

Back to Firearms and Knives